Remember Robot No. 5 in the 1986 movie "Short Circuit?" Well he's a reality now and helping insurers investigate a variety of losses.

A commercial fire in southern New York consumed a 100-year-old town landmark in late April 2014. The building housed a family-owned business and the large number of combustibles such as furniture, upholstery, and a wooden elevator shaft turned the structure into an inferno. Tremendous heat and concerns about the structure collapsing forced firefighters to combat the blaze from exterior locations, including the rooftop of the attached building.

Structural integrity remained a concern as the local fire department investigated the fire and representatives from the policyholder's insurance carrier arrived in response to the large loss. Early indications were that the origin of the blaze was an electrical box on the first floor, but because the top two stories of the five-story building had collapsed in on the structure, it was unsafe for anyone to enter.

Donan, a forensic investigation firm that has gained widespread recognition for its work with unmanned aerial vehicles (UAVs), also known as drones, thought that drones could be used to document the fire scene. After reviewing images and Google Earth views of the structure, Donan's president and CEO, Lyle Donan, didn't think UAVs would be an appropriate fit.

"There are significant logistical challenges to operating a UAV indoors and in the dark, both of which were going to be the case in this fire scene," Donan explained.

While assessing the challenges associated with the fire loss, Donan recalled a conference where he met representatives from iRobot, a company that specializes in robotic technology. "I thought to myself, why couldn't a robot work for this investigation?" Donan recalls. "There was only one problem. We didn't have a robot."

After in-depth discussions with Kim Monti, senior product manager at iRobot, Donan purchased the iRobot 510 PackBot. Monti describes the 510 PackBot as "a modular, multi-mission robot" that can accommodate a wide range of accessories and has been extensively field tested. More than 5,000 units have been delivered worldwide, most for use in military and law enforcement capacities like screening vehicles and structures for explosives and neutralizing bombs.

The PackBot has cameras in several locations to capture both still images and video. The video includes first-person views of what the robot is "seeing," as well as images of the robot itself, all of which are relayed back to the operational control unit (OCU) in real time. In New York, the operator was David Fletcher of iRobot, who explained that "just like in a first-person video game, I've got to be able to see the machine and its surroundings to maneuver it effectively."

The connection between the robot and the OCU is a wireless radio connection, according to Monti who confirmed that internet access is not required for operation. "The PackBot is designed for use in rugged terrain, so it can't rely on wireless internet or 4G."

Treads and flippers enable the robot to navigate diverse terrain, including rolling over rubble and going up and down stairs. A three-link arm can carry items up to 12 pounds at full extension and 30 pounds at closer range, which is useful for clearing debris and retrieving evidence. Both of these features were essential for the investigation. The PackBot moved over and around piles of debris from the fire, and traveled downstairs to the basement in order to document all areas of concern. The robot also located and retrieved the alarm panel from the first floor, which was one of the primary objectives for the inspection.

When asked about the cost of the robot, Donan characterized the investment as "significant," indicating an out-of-the-box price in the low six figures, but added that "the applications for the property claims industry are extensive" with fire investigations being a prime example.

While the client did not disclose what they paid for the investigation, they confirmed that the results were worth the price. "When it comes to large losses, carriers want to get things right and answer all the questions they can. There were things that needed to be seen on the first floor and in the basement, but the structure wasn't stable, so their options were limited. Partnering with us to use the PackBot enabled them to get high-quality images and video quickly and safely, at a fraction of the cost of manual demolition," Donan explained.

Close-up video and photographs of the electrical service panel and smoke detectors located in the basement were also obtained by the robot. Images showed the electrical box on the first floor as mostly intact with no surrounding burn patterns to suggest it was the origin of the fire. Investigation of the basement showed burn patterns around a work area where interviews with employees confirmed that they had been working prior to the fire and had disposed of items in the trashcan located where the images suggested the fire originated.

Local authorities closed the case citing several possible accidental causes — with the items in the trashcan being one. Donan was pragmatic in their assessment. "When a loss is covered, the insurance company pays the claim. If there is subrogation potential, they pursue it. That's what it means to be a responsible insurer," explained Ray Baker, Donan's regional fire manager. "By working with Donan to use the robot, they got conclusive answers in a safe manner, saved significant time and expense, and provided better service to their insured."

Donan said the policyholder was impressed by the entire process. "You have this building that means the world to you and it burns down and you want to know what happened," said Donan, adding that the structural issues with the building made the insured uncertain whether a cause could be identified. "Then your insurance company goes to extraordinary lengths to get you an answer. They actually brought in a robot! Nothing changes the fact that they lost this place and its history, but at least we were able to assist in determining why."

Robot aids fire investigation in Arkansas

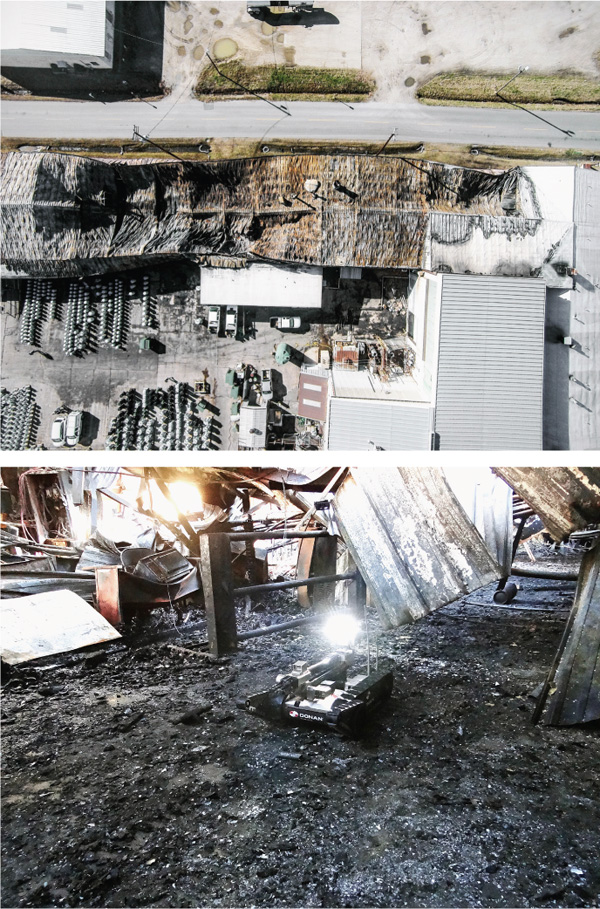

In another case, Jim Caton, IAAI-CFI, CFEI, CVFI, Donan senior fire investigator was called in to inspect a large industrial fire in Pine Bluff, Ark., in December 2014. The fire occurred in a manufacturing facility and burned for several hours. During the fire suppression, an 800×60 foot portion of the roof collapsed, prompting the carrier, Union Standard Insurance Group, a W.R. Berkley Company, to consider deploying a crane to support the origin and cause investigation.

During his site assessment, Caton observed there was sufficient clearance for Donan's robot, Scio Surveyor 7, to access the areas beneath the collapsed roof. "There was a lot of risk and cost associated with bringing in a crane to remove the roof and there was no guarantee we would be able to recover important evidence. The robot was a nondestructive alternative that could potentially identify a specific area of focus or eliminate the need for a crane altogether," explained Caton.

Caton and Union Standard claims adjuster Christopher Michels determined that utilizing Scio would benefit the investigation and claims handling by:

-

Eliminating unnecessary measures (like bringing in the crane) if the robot's assessment showed no physical evidence of value in the collapse zone,

-

Identifying areas of interest within the collapse zone to allow for more efficient use of a crane and to preserve items of evidentiary value.

Images and video captured by Scio helped eliminate several suspected causes of the fire and assisted investigators in determining that the potential for successful subrogation was very low due to the extent of the damage, the presence of numerous combustible materials and chemicals, and the age of the equipment in the area of origin. "The robot was able to provide us a more clear understanding of the fire scene as a whole. Its videos and pictures provided a 360-degree view of areas that would have otherwise only been accessible by dismantling the building piece by piece," said Michels. The fire was classified as undetermined and the investigation was closed. The robot's study eliminated the need for the crane deployment, saving substantial costs and time.

Robot technology enhances investigations

Want to continue reading?

Become a Free PropertyCasualty360 Digital Reader

Your access to unlimited PropertyCasualty360 content isn’t changing.

Once you are an ALM digital member, you’ll receive:

- All PropertyCasualty360.com news coverage, best practices, and in-depth analysis.

- Educational webcasts, resources from industry leaders, and informative newsletters.

- Other award-winning websites including BenefitsPRO.com and ThinkAdvisor.com.

Already have an account? Sign In

© 2024 ALM Global, LLC, All Rights Reserved. Request academic re-use from www.copyright.com. All other uses, submit a request to [email protected]. For more information visit Asset & Logo Licensing.