The southern part of the great state of Louisiana boasts some ofthe lowest unemployment rates in the U.S.; however, it pales incomparison to the rest of the country in statistics related toworkers' compensation and work-related injuries.

|Louisiana costs per claim for workers' comp were higher thanmost other states and growing faster for all cost componentsincluding indemnity, medical and related expenses. The duration oftemporary disability is anywhere from 8 to 16 weeks longer than inother states with a wage loss benefit system. Indemnity benefitsper claim are 40% higher than the median of all other states and,at 9% per year, are growing faster than any other state.

|All of which makes it all the more impressive when a companysets its sights on not only improving its own workers' comp lossratios, reducing the number of injuries and workers' comp claims,but far outpacing its fellow businesses in the Pelican State andemerging as a serious competitor within its field. But that'sprecisely what Danos & Curole Marine Contractors LLC (Danos)has accomplished.

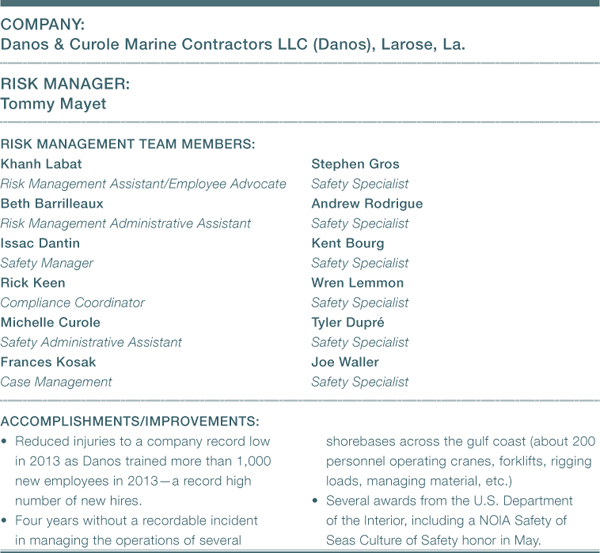

|“We have accepted the fact that we are employers in a statewrought with abuse, fraud and in need of policy reform,” says TommyMayet, Danos' risk manager. “We chose to be leaders. We havesucceeded because we attract the right people, provide themopportunities to develop, and create an environment where employeesare motivated to excel. We strive to become the organization thatothers in our industry are measured by.”

|Headquartered in Larose, La., Danos provides contract laborservices, construction and fabrication, sandblasting and paintingservices and consultants to the oil and gas industry worldwide.Founded in 1947 and currently boasting a workforce of more than1,600 employees, Danos operates in the U.S. Gulf of Mexico and gulfcoast region, Texas, Wyoming, Pennsylvania, Ohio and in severalforeign countries, supplying personnel for various on-site oil andgas industry projects and work sites, including pipelines. “Weprovide people,” says Mayet. “They are our product.”

|The work, as one would surmise, is inherentlydangerous—particularly on work sites set over water, such as oilrigs. Even traveling to the work sites can be treacherous: Boatsand helicopters are used for transportation of personnel andsupplies. Swing ropes and cranes are used to transfer personnel andsupplies from vessels to platform. Platforms include machinery,high-pressure wells, boat landings, steel decks, stairways andhandrails, all of which need continuous maintenance and upkeep tocontrol the effects of a salt water environment on steel surfacesand electrical machinery.

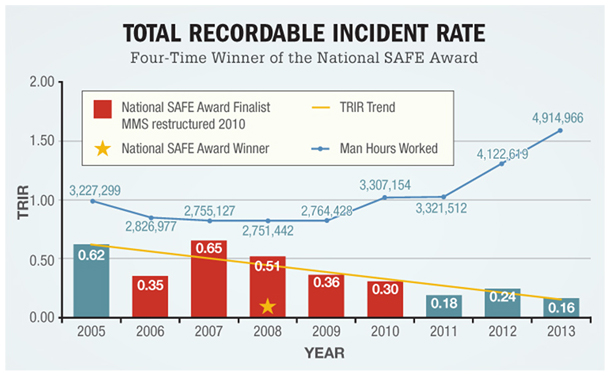

||Yet through its dedication in recent years to achievingoperational excellence, Danos has reached all-time lows in itstotal recordable incident rates at a time when the company'spersonnel, man-hours and exposures have increased tremendously. Asits time on-site and total number of personnel have grown in recentyears, incidents are on an inverse track.

|“We committed to world-class operational excellence through thedevelopment of a high-performance culture that demands world-classemployees and safety programs,” says Mayet. “As challenging asthings continue to be, we've come a long way.”

|Safety Measures On-Site

|The oil and gas industry is ultimately about people—peopleworking to provide a critical product to society, people working tobetter themselves, and people working to provide for theirfamilies, says Mayet. It is because of those people and families,he adds, that all of Danos' workers deserve to be given the tools,knowledge and support that allow them to return safely home at theend of every work day. It is an ethos that is engrained in thecompany.

|Screening becomes particularly important when recruiting newpersonnel. “We're aiming for their success, producingcontentment—which results in higher production and less incidentsand illness,” says Mayet. One technique Danos uses, prior to theone-on-one interview, is to have candidates come into the officefor an interactive interview/open house-type meeting in a commonarea—enabling recruiters as well as current employees to engagewith the candidate in order to get a better idea of that person'sknowledge and passion for the industry and to observe how theyinteract in groups. If they don't like what they see, thatcandidate isn't invited back.

|Before their first days on the job, all employees undergoorientation and five to 12 days of training, polishing their skillsand competencies, familiarizing them with the industry, safety andDanos' high-performance culture and values. The program, called“Daily Safety Management,” is designed to simulate a day in thelife of a Danos employee with regard to its safety programs,policies and culture.

|Slips, trips and falls remain workers' greatest exposure, withslippery decks and oily decks a hazard and a main contributor toaccidents. Pinch points, at which a worker can get caught inbetween loads, is another danger.

| In its effort to “get out in front” of itsemployees and prevent injuries, says Mayet, monitoring at-riskbehaviors and environments through its “W.A.T.C.H.” Program(Working Always to Control Hazards), has been essential. Theprogram rewards employees for identifying and reporting hazards.When an employee completes a W.A.T.C.H. card form using Danos'online system, certain observations are sent via e-mail to thesafety team and designated members of management based onprogrammed criteria.

In its effort to “get out in front” of itsemployees and prevent injuries, says Mayet, monitoring at-riskbehaviors and environments through its “W.A.T.C.H.” Program(Working Always to Control Hazards), has been essential. Theprogram rewards employees for identifying and reporting hazards.When an employee completes a W.A.T.C.H. card form using Danos'online system, certain observations are sent via e-mail to thesafety team and designated members of management based onprogrammed criteria.

For example, the company is currently highlighting and promotingmore reporting of near-misses so that all observations that includea near-miss go directly to management and safety leaders forfollow-up.

|“We have the capability to do the same thing for interventions,or particular types of at-risk behavior that we are emphasizing,such as hands or eyes, or fall protection,” he adds.

|Accidents will happen, of course, and when they do, employeescoming in from offshore are met at the dock or heliport by a Danosrepresentative and escorted to the nearest facility for medicalcare.

|Culture-Building 101

|The “high-performance culture” that Mayet describes has severalkey components, including communication, teaching by example,rewards for fewer accidents, performance management systems, and,when necessary, eliminating obstacles that can stand in the way offostering this culture.

|Danos hosts an annual Leadership Conference that brings togetherfield leaders from across the company for two days of sit-downmeetings with management to discuss working conditions andopportunities for improvement and development.

|A weekly safety roundtable conference call is also held, inwhich employees from various locations call in to discuss lessonslearned and safety hazards that might need attention. In 2013, anaverage of 49 employees called in each week to participate.

|Danos, he says, possesses a “bias to action,” which includes anunderstanding that all of its employees are free to exercise theirown stop-work authority when necessary. If a worker judges asituation to be risky, the employee is empowered to take a standwith a client and find a safer way to proceed.

||“They can stand up for what they think is better and differentand help to avoid an incident,” says Mayet. “That is absolutegospel, and how it has to be done. We want to empower you and allowthem to challenge that customer—not in a combative manner—and theyhave the confidence in knowing that we will back them up.”

|The proof is in the results. Danos manages the operations ofseveral shorebases across the gulf coast (about 200 personneloperating cranes, forklifts, rigging loads, managing material,etc.) These are 7-days-a-week, 24-hour operations with high demandsfor delivering critical equipment and supplies—and the companycurrently stands at four years without a single recordable incidentin this service line.

|“The risk profile of the work we perform is very high across thespectrum of work in the industry,” Mayet adds. “Our reputation isbuilt on developing relationships with our customers. We don'tpromote ourselves as a low-cost provider [of labor]. We need toprovide the best employees at a level of world-class operationalexcellence.”

|Confident Claims Execution

| Because of the confidence Mayet and hisdepartment have gained in the company's ability to control itsworkers' compensation claims and losses, Danos in the last threeyears has increased the SIR deductible with its carrier from$50,000 in 2012 to $75,000 in 2013 to the current $100,000 in ourcurrent policy year.

Because of the confidence Mayet and hisdepartment have gained in the company's ability to control itsworkers' compensation claims and losses, Danos in the last threeyears has increased the SIR deductible with its carrier from$50,000 in 2012 to $75,000 in 2013 to the current $100,000 in ourcurrent policy year.

“We crunched the numbers, and we were willing to put more skinin the game,” he says. “We have a near 40-year relationship withour workers' compensation, general liability and auto liabilityinsurance carrier (The Gray Insurance Co. in Metairie, La.), whichhas led to the development of valuable relationships with theirin-house claims adjusters.”

|Managing the cost of claims has become a critical task for allemployers, especially in a state where total costs per claim havebeen increasing at an average of 8% per year. Danos works closelywith its carrier in the management of its claims—and establishedthe position of Employee Advocate to work closely with employeeswho do become injured and are forced to spend time away from activeduty.

|Khanh Labat, Danos' assistant risk manager, assumed thisposition in 2011 and she serves as what Mayet describes as “thedelicate voice on the phone” who manages the employee through theentire process when they become injured. Mayet knows all too wellthat the onus is on the employer to manage that relationship fromstart to finish, especially when any cases of conflict can arise,lest they ponder any kind of legal action.

|If that relationship is managed mindfully, he adds, far moreoften than not things are brought to an agreeable point for allinvolved. The result for Danos has been a dramatic decrease inclaims that have led to litigation.

|“Khanh manages the person; the claim is managed by our claimsadjusters,” says Mayet.

|“The difference we have made in the lives of the people in ourindustry is what we are most proud of as a company,” he adds.“We've made great strides and celebrated great successes, but everyday we continue to endeavor for that perfectly safe day. We knowthe striving, learning and improving can never stop.”

Want to continue reading?

Become a Free PropertyCasualty360 Digital Reader

Your access to unlimited PropertyCasualty360 content isn’t changing.

Once you are an ALM digital member, you’ll receive:

- All PropertyCasualty360.com news coverage, best practices, and in-depth analysis.

- Educational webcasts, resources from industry leaders, and informative newsletters.

- Other award-winning websites including BenefitsPRO.com and ThinkAdvisor.com.

Already have an account? Sign In

© 2024 ALM Global, LLC, All Rights Reserved. Request academic re-use from www.copyright.com. All other uses, submit a request to [email protected]. For more information visit Asset & Logo Licensing.