Last month's train disaster in the small Quebec town ofLac-Mégantic was North America's deadliest rail accident in twodecades.

|On July 6, a train hauling tankers of crude oilderailed in the center of Lac-Mégantic, where it exploded,killing 47 people and decimating the downtown area. Followingthe accident, the Canadian government moved to shut down Montreal,Maine and Atlantic Railway (MMA), the company operating the runawaytrain, when MMA said it carried insufficient insurance coverage topay for the cleanup costs.

|The government has since decided to allow the railway operate through earlyOctober. It's clear the liability debate is far from over, and thetragic accident may carry regulatory and risk managementimplications. It's also clear that professionals in the claimscommunity will need to enhance their knowledge of the railmechanics. What causes rail failure, and when is subrogation anoption? Below, we delve into the technical side of rail failures.In the forthcoming October issue of Claims Magazine, we'llexplore the type of claims that stem from such a disasterand considerations for claims adjusters.

|Click on “Next” at the bottom right to viewmechanisms for rail failure.

|Rail Failures

|Private railroad turn-outs service many industrial facilities.Rail failure can occur for a variety of reasonsand can cause substantial property loss, along withpossible personal injuries.

|

Figure 1 to the left is a view of a railfailure that occurred at the lead truck (front wheels) of a diesellocomotive on a private rail siding.

|The locomotive derailed, resulting in damage to the tractionwheels as well as loss of usage of the turn-out while repairs weremade.

|Figure 2 below shows the fracture surface ofthe rail, characterized by an older rusted fracture and the freshfinal fracture of the 150 lb/yard steel rail. It was apparentthere was sufficient mechanical stress in the rail to cause in ametal fatigue related fracture.

|

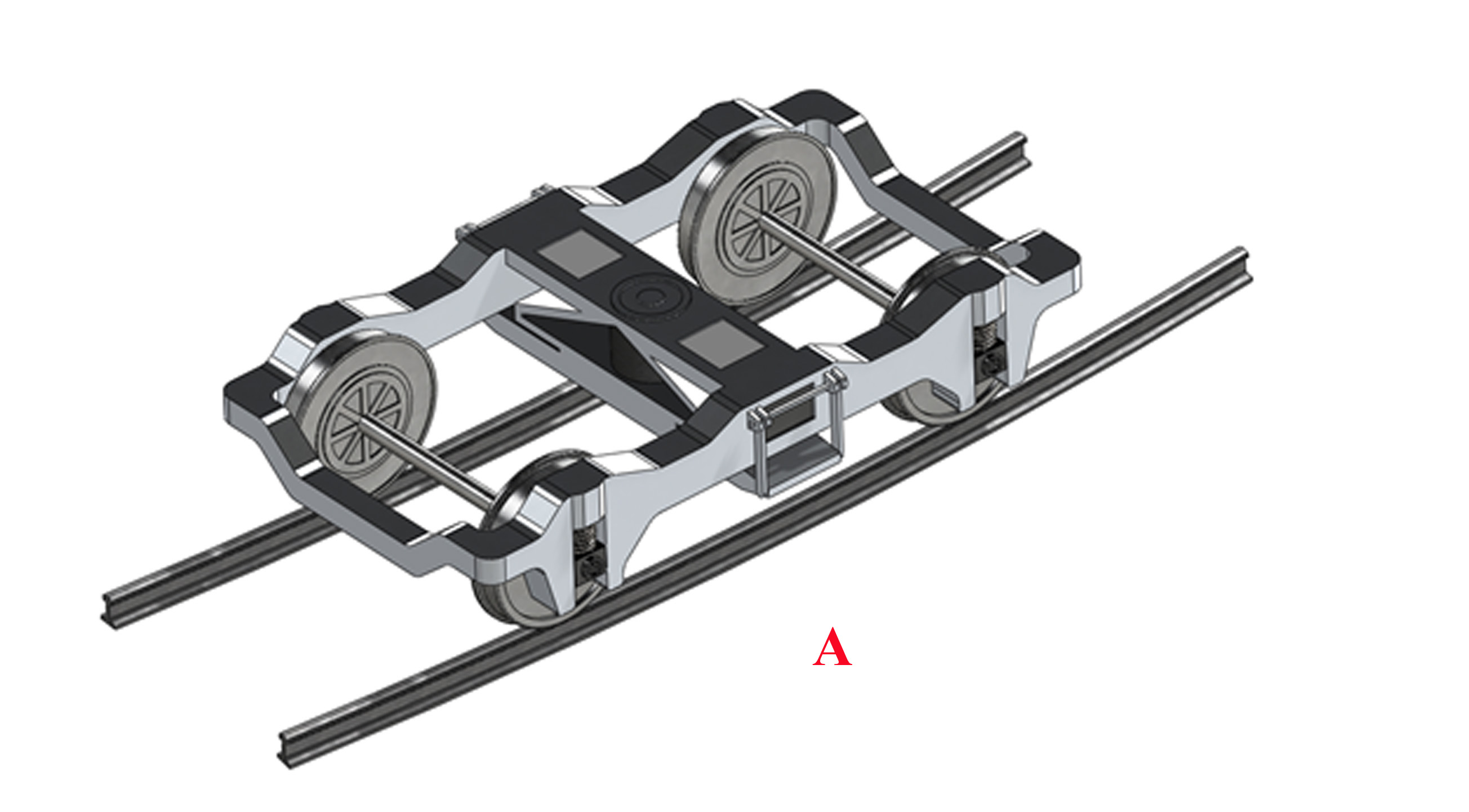

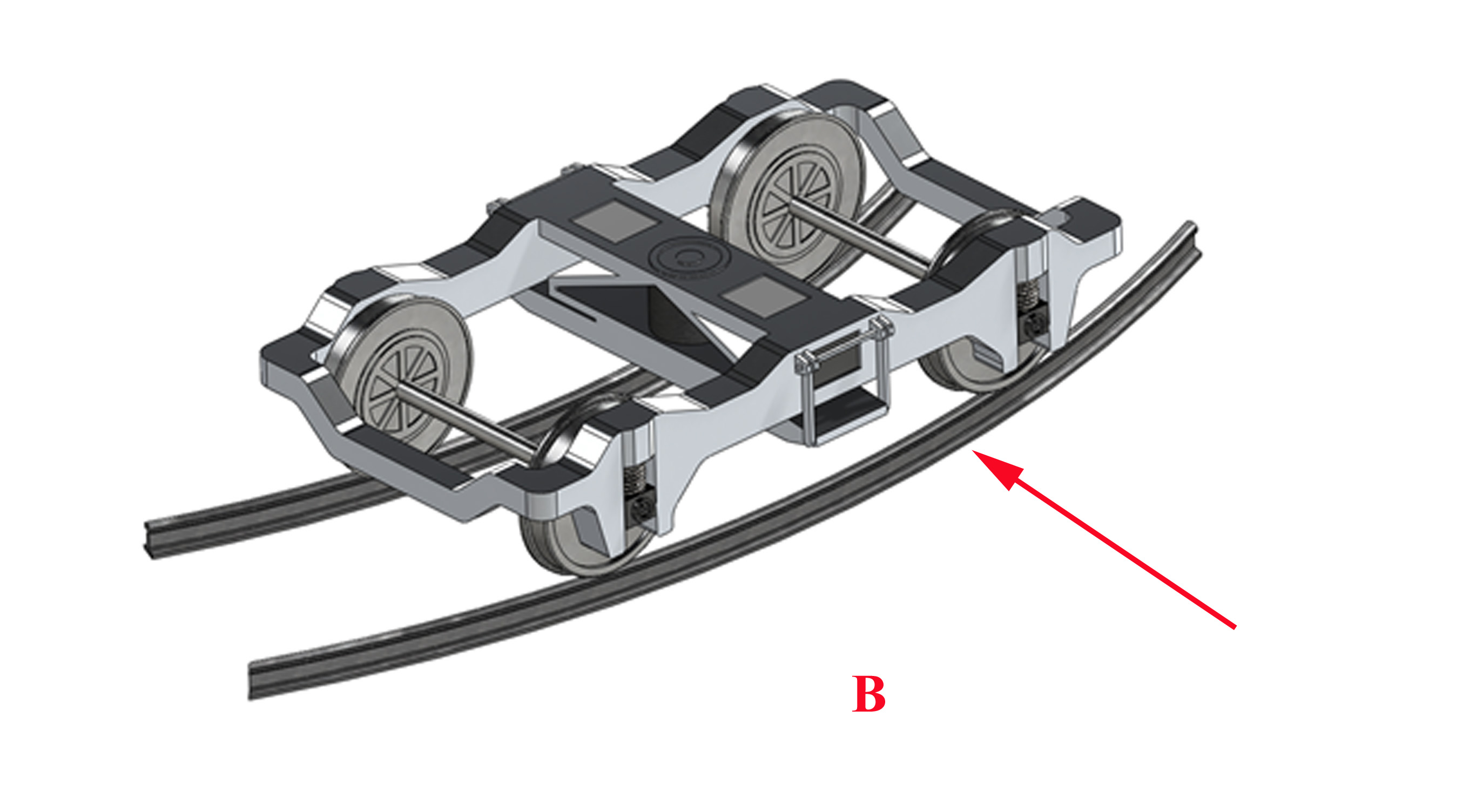

In Figure 3A below, a railroad truck(set of wheels) is rolling on a moderate curve.  Figure 3B (to the bottomright) shows a truck rolling on a curve of lesser radius, whichcauses increased stress in the rails (red arrow) as a result of thetruck trying to straighten the curve. Many railroads have minimumradius specifications for private rail facilities.

Figure 3B (to the bottomright) shows a truck rolling on a curve of lesser radius, whichcauses increased stress in the rails (red arrow) as a result of thetruck trying to straighten the curve. Many railroads have minimumradius specifications for private rail facilities.

For instance, Reference 1 requires a minimum radius of 574 feetfor acceptable operation in private railroad yards. This tends tominimize the mechanical stress in the track, reducing trackmaintenance and track failure.

|For the failure shown in Figures 1 and 2, theradius of the track was significantly less than recommended,suggesting a design defect is the probable cause offailure. Other evidence of a low radius curve is the existenceof several wheel burns on the track.

|

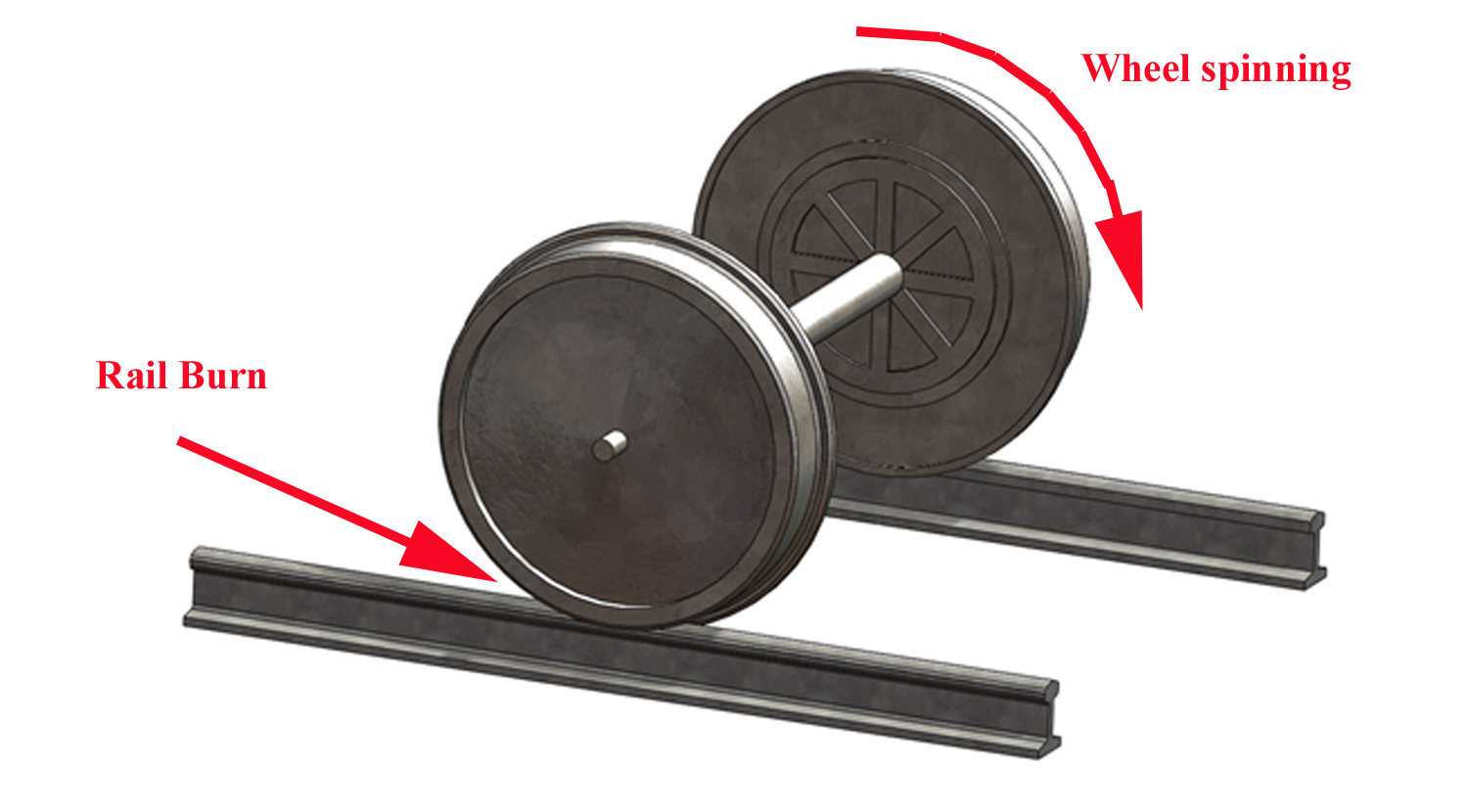

A locomotive starting to move a train may encounter tractionwheel slippage, which causes a characteristic scuffing mark on thetrack called a rail burn, as shown above. Rail burn sites maybe a future origin of a rail fracture. The diagram below shows themechanics of a rail burn. Short radius curves increase the rollingresistance of rail cars, making it harder to move.

|

This case study serves to illustratethat a deficient design of a private sidetrack can cause asignificant property loss.

|Photo source: Standard specification for the design andconstruction of private sidetracks, CSX Transportation, Office ofthe Vice-President – Engineering, Jacksonville, Florida

Want to continue reading?

Become a Free PropertyCasualty360 Digital Reader

Your access to unlimited PropertyCasualty360 content isn’t changing.

Once you are an ALM digital member, you’ll receive:

- All PropertyCasualty360.com news coverage, best practices, and in-depth analysis.

- Educational webcasts, resources from industry leaders, and informative newsletters.

- Other award-winning websites including BenefitsPRO.com and ThinkAdvisor.com.

Already have an account? Sign In

© 2024 ALM Global, LLC, All Rights Reserved. Request academic re-use from www.copyright.com. All other uses, submit a request to [email protected]. For more information visit Asset & Logo Licensing.